On Monday it was the birthday for one of our kids. As that kid absolutely isn’t into gifts we had to come up with something else. As a surprise my wife came to Berlin and payed us a visit and we had fancy donuts and a cheese fondue for dinner. That was great fun.

Got myself a Nintendo Switch for a few weeks. Just to try whether it might entertain me and the kids for a while. And it’s surprisingly good so far. I like the fact that you can play on the go or on the big screen in multi-player mode. Also their controller concept is pretty versatile. In two month I’m checking whether I’ll keep it or not.

Got an Xbox 360 with Kinect collecting dust here since years. The concept was great. But then again we didn’t really made use of it.

I finally managed to get Klipper working on my 3D printer. Klipper is an alternative firmware to control the printer. The original firmware for my Creality Ender 3 V2 is based on the popular Marlin Firmware. That sits directly on the controller board (MCU) of the printer and controls all the hardware component and executes the printing of G-Code files.

Klipper in contrast is modular. Only a very basic firmware is flashed onto the controller board of the printer and acts as counterpart to the more complex Klipper Host process that sits on a computer. In my case a RaspberryPi 4. The computer hosting the Klipper host process is usually more powerful than the MCU of the printer and can perform more stuff to make for a smooth print. The Raspberry Pi is connected via USB-Serial to the printer to connect Klipper host process and Klipper firmware.

The downside is, that one has to configure Klipper properly for the printer. There are readymade profiles for popular printers available that should give a good start. But I have modified my Ender quite a bit and thus had to do a whole lot of calibrations for the Dual Z-Axes, the direct drive Extruder, Filament sensor, CR-Touch probe etc.

This process was what ticked me off last time I tried. I just couldn’t get a reliable print out with Klipper. And I didn’t had issues with my Marlin Firmware to begin with. So back then, I switched back to Marlin. This time I wanted to get it working to be able to support a friend who just recently got a used Ender 3 V2 with Klipper firmware.

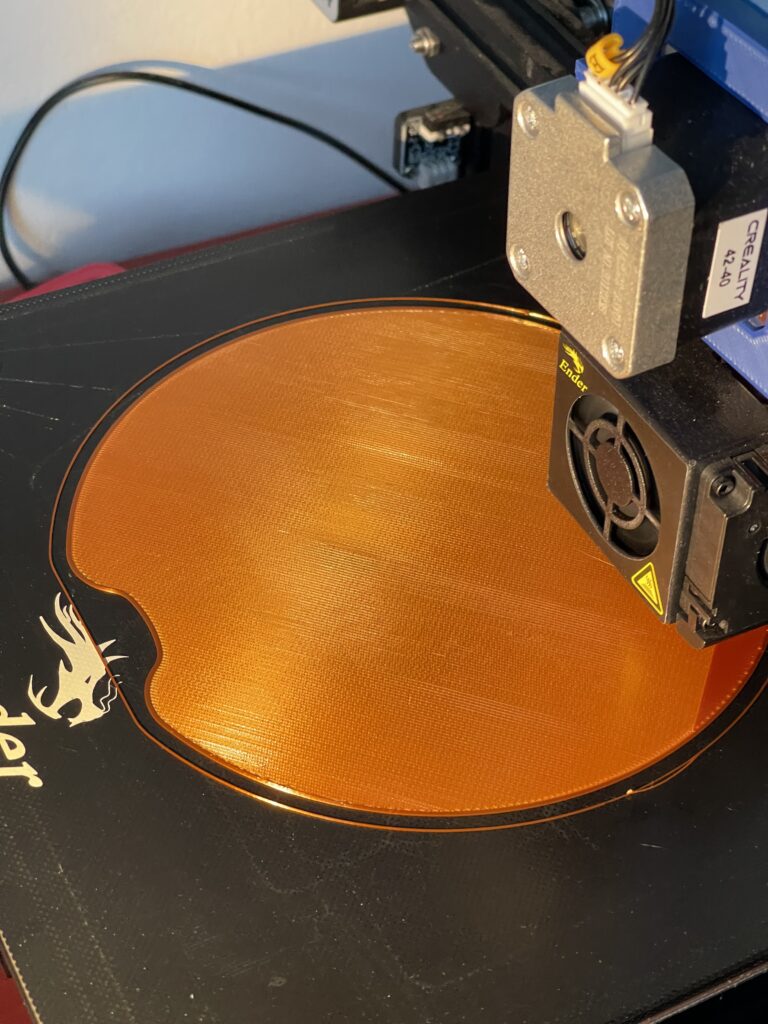

Eventually I got it all running and even installed “Klipper Advanced Mesh & Purging” (KAMPS) and configured Input Shaping thanks to some helpful articles. KAMPS will analyse the G-Code files and then do the bed calibration with the probe just on the area of the bed where the model will be printed. This gives much more accurate information because it just probes the small printing area with the same amount of probe points. Makes for a better 1st layer.

Input Shaping is voodoo where you measure the printers vibrations during movements and calculate resonance frequencies and the best way to compensate these vibrations during print. I had to solder a sensor and cable to connect the motion sensor to the raspberry pi and then conduct the measuring (fortunately that only needs to be done on hardware changes on the printer).

Finally I was able to produce some acceptable prints that I promised to a friend.

On Saturday we did a day trip to Binz. First time since 2017 that my wife had been there. It was great. The weather was OK and we had good lunch in the famous “Strandhalle” and took a walk on the beach. It wasn’t too crowded as its really off-season at the moment and the weather wasn’t inviting for a long walk.

The lake had ice last weekend already. But it was just 5cm and a friend took the effort to make a hole so we could at least dip in.